Automatic Rotary Packing Machine

| Machine introduction | This machine is a classic model for pre-made bag package fully automated packaging. It can independently complete bag pick-up, date printing, opening, filling, vibrating, heat-sealing, shaping and outputting finished products. It’s suitable for many materials and wide range of packaging bags; it’s intuitive and easy operation, easy to adjust speed; it can quickly change the specifications of packaging bags, equipped with automatic detection and safety monitoring functions, to reduce the loss of packaging materials, ensure the sealing effect and perfect appearance. The whole machine is made of stainless steel, which guarantees more sanitation and safety. | ||||||

| Technical features | This machine High quality and performance Good stable and also good machine exterior Own extensive range in filling productions Easy operate by touch-sensitive screen, PLC and electric control system Friendly man-machine interface Speed can be adjusted by frequency conversion within the range. Volume changed easy by adjusting handle in the paste filler Prefect sealing system Good safety secure and so on | ||||||

| Safety | No bag – no filling- no sealing, machine alarm. Bag opening miss- no filling-no sealing, machine alarm. Machine stop or alarm when the air pressure is abnormal Error position display at the control panel. Control panel locate on the right side top of the machine. Outside of the machine and all the parts which touch production all made by stainless steel. There are several safety doors made by aluminum Profile Frame. Machine surface can be wash by water and brush by cloth. | ||||||

| Bag applications | Flat bags, Stand-up Bags, Doypack, Zipper bag | ||||||

| Application products |

| ||||||

Machine details:

| Bag types | Stand-up bag, Portable bag, 4-side sealing bag, 3-side sealing bag, paper bag, etc., and all kinds of compound bags |

| Bag sizes | W:100-200mm L:100-350mm |

| Filling range | 5-1000g |

| Packing speed | 10-60bags/min (depended on the product status and filling weight) |

| Compressed air | 0.6m3/min(supply by user) |

| Total power | 5.0KW |

| Machine dimension | L2500 x W1460 x H1400mm |

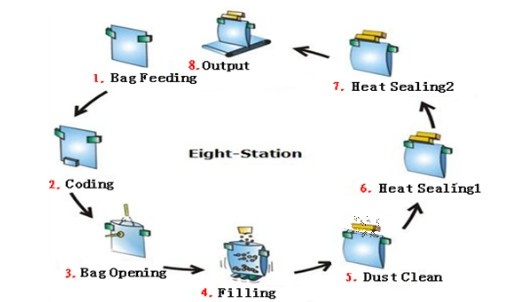

Station 1 Bag dispensing (Bag feeding)

Feed many pouches or bags in the bag magazine, which can move up and down, and you can

feed bags very easily when it moves down, and when it moves up, there are a mechanical arm with two vacuum caps will take bag up and then transmit it to the mechanical gripper on the rotary table.

Station 2 Coding (Date Printing)

Ribbon printer, Ink-jet printer for optional

Station 3 Bag Opening

Using air to open the bag, and an opening detection device inserts into the

opened bag to expanding it and detect if it is open or not.

Station 4 Filling

There are an opening detection device insert into the open bag or pouch to expanding it and detect if it is open or not.

No open no filling no sealing

Station 5 Dust Clean

Clean the dust on the bag mouth for better heat sealing

Station 6 Heat sealing 1

To seal the bag with a couple of heat sealing air bar

Station 7 Heat sealing 2

Second sealing for sealing stronger

Station 8 Forming and product output

To make the sealing stable and preventing from wrinkling with a couple of cold press, then output the finished production automatically. (the sealing pattern with net or straight lines for your option)

Automatic Rotary Packing Machine

| Machine introduction | This machine is a classic model for pre-made bag package fully automated packaging. It can independently complete bag pick-up, date printing, opening, filling, vibrating, heat-sealing, shaping and outputting finished products. It’s suitable for many materials and wide range of packaging bags; it’s intuitive and easy operation, easy to adjust speed; it can quickly change the specifications of packaging bags, equipped with automatic detection and safety monitoring functions, to reduce the loss of packaging materials, ensure the sealing effect and perfect appearance. The whole machine is made of stainless steel, which guarantees more sanitation and safety. | ||||||

| Technical features | This machine High quality and performance Good stable and also good machine exterior Own extensive range in filling productions Easy operate by touch-sensitive screen, PLC and electric control system Friendly man-machine interface Speed can be adjusted by frequency conversion within the range. Volume changed easy by adjusting handle in the paste filler Prefect sealing system Good safety secure and so on | ||||||

| Safety | No bag – no filling- no sealing, machine alarm. Bag opening miss- no filling-no sealing, machine alarm. Machine stop or alarm when the air pressure is abnormal Error position display at the control panel. Control panel locate on the right side top of the machine. Outside of the machine and all the parts which touch production all made by stainless steel. There are several safety doors made by aluminum Profile Frame. Machine surface can be wash by water and brush by cloth. | ||||||

| Bag applications | Flat bags, Stand-up Bags, Doypack, Zipper bag | ||||||

| Application products |

| ||||||

Machine details:

| Bag types | Stand-up bag, Portable bag, 4-side sealing bag, 3-side sealing bag, paper bag, etc., and all kinds of compound bags |

| Bag sizes | W:100-200mm L:100-350mm |

| Filling range | 5-1000g |

| Packing speed | 10-60bags/min (depended on the product status and filling weight) |

| Compressed air | 0.6m3/min(supply by user) |

| Total power | 5.0KW |

| Machine dimension | L2500 x W1460 x H1400mm |

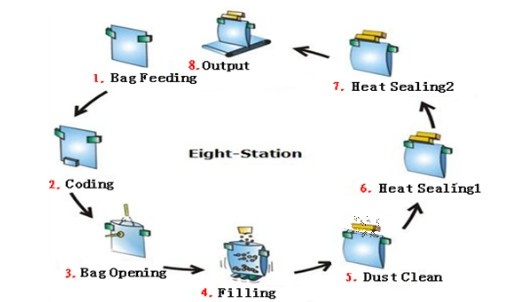

Station 1 Bag dispensing (Bag feeding)

Feed many pouches or bags in the bag magazine, which can move up and down, and you can

feed bags very easily when it moves down, and when it moves up, there are a mechanical arm with two vacuum caps will take bag up and then transmit it to the mechanical gripper on the rotary table.

Station 2 Coding (Date Printing)

Ribbon printer, Ink-jet printer for optional

Station 3 Bag Opening

Using air to open the bag, and an opening detection device inserts into the

opened bag to expanding it and detect if it is open or not.

Station 4 Filling

There are an opening detection device insert into the open bag or pouch to expanding it and detect if it is open or not.

No open no filling no sealing

Station 5 Dust Clean

Clean the dust on the bag mouth for better heat sealing

Station 6 Heat sealing 1

To seal the bag with a couple of heat sealing air bar

Station 7 Heat sealing 2

Second sealing for sealing stronger

Station 8 Forming and product output

To make the sealing stable and preventing from wrinkling with a couple of cold press, then output the finished production automatically. (the sealing pattern with net or straight lines for your option)